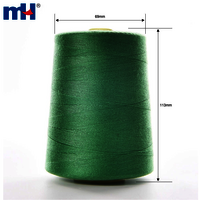

Sewing Threads 20S/3 Polycore Spun Sewing Thread Polyester Polyester Core Spun Sewing Threads

Product Details:

- Length 1000yds to 20000yds/cone Yard

- Material 100% Polyester

- Character Spun

- Properties Dyed

- Style Core Spun Yarn

- Usage Cross Stitch Knitting Stitching Sewing

- Yarn Type Spun

- Click to View more

Sewing Threads 20S/3 Polycore Spun Sewing Thread Polyester Polyester Core Spun Sewing Threads Price And Quantity

- 3000 Piece

- 1.1 USD ($)/Paint

Sewing Threads 20S/3 Polycore Spun Sewing Thread Polyester Polyester Core Spun Sewing Threads Product Specifications

- 400 colors

- 1000yds to 20000yds/cone Yard

- Light in Weight Washable High Tenacity Eco-Friendly Low Shrinkage Anti-Piling

- 100% Polyester

- Spun

- Cross Stitch Knitting Stitching Sewing

- Spun

- Dyed

- 0.5kg to 2kg/cone Kilograms (kg)

- Dyed

- Core Spun Yarn

- 20S/3

Sewing Threads 20S/3 Polycore Spun Sewing Thread Polyester Polyester Core Spun Sewing Threads Trade Information

- Ningbo/Shanghai /Yiwu /Shenzhen

- Days after Acceptance (DA) Delivery Point (DP) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 35 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- 1000yds to 20000yds/cone, or 0.5kg to 2kg/cone

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- OEKO-TEX Standard 100 Annex 6 Class 1

Product Description

Polyester Polyester Core Spun Sewing Thread

Corespun threads are made by wrapping a staple polyester or cotton wrapper around a continuous filament bundle of polyester fibers during spinning and then plying these yarns into a sewing thread.

There are two types of corespun sewing thread. They are poly wrapped poly core and the cotton wrapped poly core

Normally it has counts as 12s2, 20s2, 28s2, 29s2, 36s2, 40s2, 45s2, etc.

Oeko Tex Standard 100 Annex 6 passed

The continuous filament polyester core makes up approximately 60% of the thread construction.

With 400 colors, it can match perfectly to the sewed fabric

It has outstanding sewability and creates a smoother, softer handle to the sewn seam when compared with conventional sewing threads, its strength also 15%-20% higher than conventional sewing threads.

Core spun threads are recommended for use on outdoor performance, sportswear, woven outerwear and fashion jackets, jeans, leather products, etc.

MH Factory

MH has three industry zones for thread factories, with 220,000m2 plant area and 1100 workers, equipped with high-standard machines and a strict manufacturing management system

With an annual production capacity 30000+ tons, that means about 2000x40'HQ per year.

Ningbo MH

Ningbo MH was established in 1999, specialized in garment accessories and tailoring materials.

At present, MH owns nine factories located in 3 industry zones, with a 382,000m2 plant area and 1900 workers, producing polyester sewing thread, embroidery thread, lace and embroidery, ribbon and webbing tapes. MH also set up long term cooperation with 1500 manufacturers for 10000 different kinds of tailoring material and fabric.